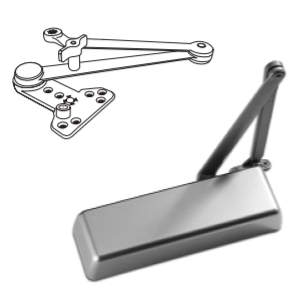

PDQ 7101-BC-EDA-HO Grade 1 Institutional Closer, Backcheck, Extra Duty - Hold Open Arm

Product Details

*PDQ 7101-BC- EDAHO Grade 1 Institutional Closer, Backcheck, Extra Duty - Hold Open Arm * PDQ offers a comprehensive line of door closers designed and manufactured to ensure superior performance and reliability. They offer the perfect combination of reliability, appearance, and durability. With a wide range of models and features, PDQ has a door closer for most applications.

The full metal cover option requires to specify handing (in comments box).

Closer Mounting: Parallel Arm (PUSH SIDE) mounting.

FEATURES:

- Heavy duty, fully featured architectural style door control.

- High strength cast iron body and forged steel arm assembly provide maximum durability and reliability in the most brutal environments.

- Backcheck positioning valve feature provides a consistent backcheck snubbing range for regular, top jamb and parallel arm applications, preventing costly damage during forceful opening of the door.

- The 7100 series has a fully adjustable spring range that can be set to meet barrier free requirements.

- Maximum 3" reveal for Top Jamb.

- 5lb. Barrier Free Spring Setting for ADA Compliance.

- 6 Additional Spring Settings that Provide 17% More Adjustment Capability to Find that Sweet Spot for Optimal Door Closing Action.

- Barrier Free Settings Available on Both Regular/ Top Jamb and Parallel Arm Applications.

HANDING: - Non-handed. OPERATION: - Rack and pinion design. BODY: - High Strength Cast Iron. ARMS: - Forged steel main arm. - Flat style arm assembly. ARM OPTIONS: - Hold open arm. - Track/Track Hold Open. - DS/DSHO heavy duty parallel stop arm. - Spring Cushion Stop for DS/DSHO. - EDA (Extra Duty PA Arm). PISTON: - Hardened steel, 1-1/2" diameter. ADJUSTMENT: - Adjustable controlled closing. - Separate hydraulic backcheck standard. - Backcheck positioning valve standard. - Separate sweep, latch, backcheck intensity and backcheck positioning valves. - Optional delayed action (in addition to backcheck). ADJUSTMENT VALVES: - All Adjustment Valves are STAKED. FACTORY DEFAULT SPRING SETTING: - Size 3. SIZE: - Adjustable BF 1 through 6. MOUNTING: - Mounting hole pattern retrofits LCN 4040. - Tri-packed for regular, top jamb and parallel arm installations. - Includes fasteners for hollow metal, wood or aluminum doors and frames. - Sex nuts and bolts standard. - Self drilling self tapping screws available. COVER: - Full plastic cover standard (non-handed), optional full metal cover available (handed) FINISHES: . - 605 (US3) Polished Brass, 625 (US26) Polished Chrome, 689 (US28) Aluminum, 695 (N/A) Duro Bronze, 696 (US4) Gold. FINISHES - SPRING CUSHION STOPS: - 605 (US3) Bright Brass (PVD), 613 (US10B) Oil Rubbed Bronze (PVD), 630 (US32D) Satin Stainless Steel.

Note: PVD (Physical Vapor Deposition) coated finishes offer outstanding resistance to wear, durability and corrosion.

CERTIFICATIONS, LISTINGS, COMPLIANCES: - UL228 listed. - ANSI/UL 10C listed for labeled swinging fire doors rated for up to and including 3 hours. - Certified to ANSI/BHMA A156.4-2006 Grade 1.

PDQ 7101BCRDAHO,7101BCEDABCHO PDQ, PDQ 7101EDAHO, PDQ 7101 EDA HO 689, PDQ 7101, 7101 PDQ, PDQ 7101EDA, PDQ 7101 689, PDQ 7101 EDA HO 689, PDQ 7141

Trusted Since 2001

Trusted Since 2001

.svg)